One Stop Solution for your Product Manufacturing

Get your products manufactured with high precision and a diverse variety of materials. Choose from various available technologies and a list of materials suitable for your production needs.

We make your product design and development affordable and easier with one of the largest networks of production units. Get in touch with our expert to have a 30-minute free consultation which will help you choose the right technology and material.

We have our own centres of advanced manufacturing in Coimbatore, Mangalore, Trissur, Tiptur, Thane, Mumbai, Bangalore, and Gulbarga.

Polymer 3D Printing services are provided using industrial grade 3D Printers and a wide range of materials for a variety of applications. Different materials are available for various applications. Metal reinforced products can be designed to have both metal and polymer properties.

We offer custom metal parts in Aluminum, Bronze, Copper, Stainless Steel, and other materials using our low-cost metal 3D printing solutions. With sintering and de-sintering processes included in every product’s manufacturing, components ranging from minute parts to full-size components can be manufactured with a high quality finish.

Tool design and prototyping are made easier with 3D printed molds. Vaccum forming and casting at a low investment and with easy access. Based on the casting material, customised tool fabrication and manufacturing can be done by material experts.

Our Applications

Dental

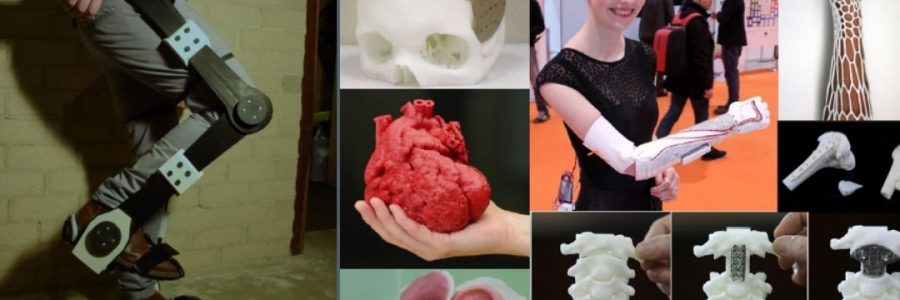

Healthcare will also benefit greatly from advances in 3D printing. 3D printing is already being used to create dental prostheses, hearing aids, and custom scaffolding for joint replacement and reconstructive cosmetic surgery. The promise of printing functional human tissues could pave the way for 3D printing organs like kidneys to aid in drug testing and even directly replace failing organs.

A) Crowns & Bridges

The use of crowns or bridges to correct damaged or missing teeth is one of the most common orthodontic procedures. Because the process can be completed by the dentist himself, additive manufacturing allows us to produce crowns quickly. It is one of the most common 3D printing applications in dentistry. It is possible to scan the patient’s teeth, model them, and then print the crown directly. This method saves time, and if an error occurs, the professional can modify and reprint the crown.

D) Dental Implants

Additive manufacturing is also used in dental implant surgery. To replace a missing tooth, it is possible to create a 3D model. Indeed, 3D printing allows for faster and more accurate tooth replacement than traditional methods. It is also a simple and cost-effective method, with a high-quality end result.

Healthcare

Healthcare will also benefit greatly from advances in 3D printing. 3D printing is already being used to create dental prostheses, hearing aids, and custom scaffolding for joint replacement and reconstructive cosmetic surgery. The promise of printing functional human tissues could pave the way for 3D printing organs like kidneys to aid in drug testing and even directly replace failing organs.

Automotive

The benefits of 3D printing are likely to revolutionisse many industries. The automotive and aerospace industries benefit from much shorter lead times than with associated traditional engineering methods such as casting or machining, allowing for much faster development and testing of components. In the future, it may even be possible for large components or even entire cars to be entirely 3D printed!

Electronics & Robotics

Integration of electronic components and circuitry in 3D printed components, or even study the electronics and robotics that will control the manufacturing processes of the future.

Textile Engineering / Fashion Technology

After agriculture the most employment generation industry in India is textile industry. It offers direct employment to over 35 million people. Fashion is all the buzz – 3D printing is the fashion of the future. Overproduction and dead stock are the biggest problems in textile industry, this can be minimized or eliminated over time.

Architecture

3D printing is poised to have a dramatic impact upon architecture, building design and manufacturing, with entire houses already produced in China with giant 3D printers. 3D printing allows building designers to experiment with shapes and geometries in design that may not be financially viable with existing building techniques.